FLSmidth

FLSmidth is a full flowsheet technology and service supplier to the global mining and cement industries. They help their customers improve performance, lower operating costs, and reduce environmental impact.

With their MissionZero programme, they have set a target of providing solutions for zero-emissions mining and zero-emissions cement production by 2030, supporting a green transition built upon sustainable materials. Their operations span the globe and comprise close to 11,000 employees across more than 60 countries.

Engineering the green shift

- sustainable solutions for the mining industry

In line with driving a sustainable future, the mining industry is facing increasing pressure to adopt greener practices, and FLSmidth is committed to leading this change. Focused on innovation and mechanical design, the project aims to transform recycling processes within the industry. FLSmidth’s vision is to push the boundaries of sustainability, making it easier for their clients to embrace green solutions, while actively contributing to the green transition - especially in a sector where these efforts can be particularly challenging.

In late summer of 2022, FLSmidth reached out to Kirkholm due to our expertise in mechanical engineering and equipment development. At the time, FLSmidth was collaborating with the Danish Technological Institute (DTI) to tackle the challenge of separating steel and rubber from used mill liners and inserts in mining operations, aiming to improve and innovate its recycling capabilities. DTI had identified pyrolysis as a promising technology for this task and referred FLSmidth to a competent partner who could bridge the gap from concept to functional machine, which led them to Kirkholm.

Defining scope and the task itself

We appointed a project manager, and it quickly became clear to him and his team that this was not a typical project. Unlike projects with clear requirements specifications, this was an innovation project focused on new development, where both the challenges and solutions were unknown from the outset. This made Kirkholm’s role unique—not only to develop the solution but also to drive the innovation process by exploring, defining, and shaping the task itself.

Our project team maintained a continuous dialogue with FLSmidth to address the evolving needs of the innovation project. By December 2022, concept development was progressing well. Kirkholm played a pivotal role in driving the process forward, especially when questions arose that neither FLSmidth nor DTI could fully answer. This phase highlighted our ability to navigate projects with inherent uncertainty, where the solutions were still being discovered, all while maintaining momentum and ensuring steady progress.

From concept to functional machine

One of the first major milestones was aligning expectations with FLSmidth. Given the innovative nature of the project, it became clear early on that a fixed requirements specification was not feasible. In response, Kirkholm adapted its project model to embrace an agile and iterative approach, allowing flexibility in navigating the unknowns. Designers and engineers took on a range of roles—from design and construction to supplier coordination—ensuring that the project maintained momentum despite ongoing uncertainties.

A prototype was developed, built, and tested in Denmark, serving as a significant turning point. It provided tangible proof of concept and demonstrated process-optimized functionality for full-scale production. Throughout the project, additional customer requests were incorporated, highlighting the dynamic, evolving nature of the work. The team’s ability to remain flexible and adjust to emerging requirements was crucial to the project’s success – as it always is in innovative projects.

Technology and technical design

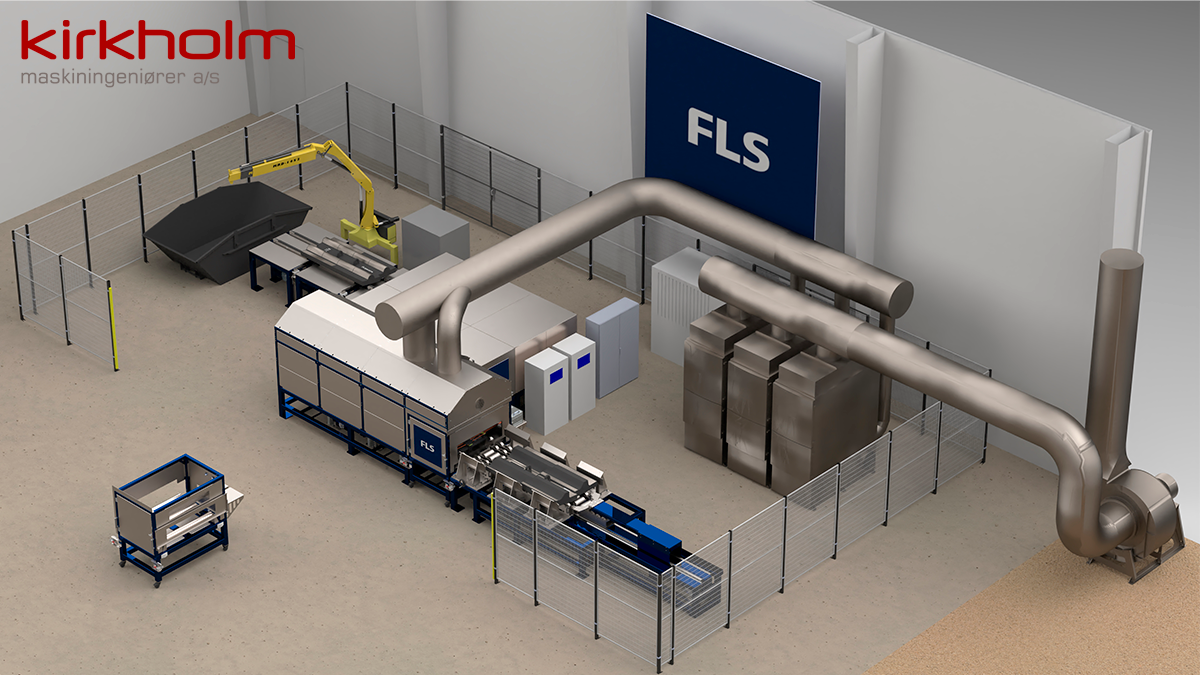

The project centered on the pyrolysis process, which separates steel and rubber through heating. But to turn the concept into a reliable machine required innovative mechanical engineering and process optimization.

Kirkholm’s design featured a range of modular systems to facilitate separation. The machine was required to handle two distinct types of workpieces. Through close collaboration with suppliers and partners, Kirkholm created a solution that was both robust and ready for the future.

A multidisciplinary approach delivers great customer value

The project required a broad set of competencies, ranging from project management and conceptualization to mechanical design, CFD simulations, and supplier coordination. This resulted in a multidisciplinary approach that provided great value to FLSmidth and the project. With a single point of contact, FLSmidth had easy access to all information and quick communication. Kirkholm streamlined solutions across disciplines, ensuring seamless integration, reducing complexity, and taking full responsibility for addressing challenges and delivering optimal results. This approach demonstrated our ability to take on end-to-end development tasks, even when the initial scope was undefined. The agile project approach and the adaptability of the team proved critical to the success of the development process.

Enhanced collaboration and clarity through Virtual Reality

Effective communication is essential when you dealing with a complex project. To bridge the gap between design and understanding, Kirkholm used Virtual Reality (VR) technology. VR models allowed FLSmidth and partners to visualize the machine’s structure and functionality, enhancing their grasp of the project’s scope and potential. By visualizing the machine in VR, Kirkholm made it easier for key stakeholders, such as electrical engineers, to understand their roles and requirements during the assembly process.

Key reflections and lessons learned

One of the most valuable insights from this project was the importance of defining the task itself — and how to do so in collaboration with FLSmidth. Without a formal requirements specification, Kirkholm’s engineers took the lead in shaping the project’s direction, a process that required flexibility, patience, and technical excellence. By doing so, Kirkholm showcased our capacity to handle the unknown and guide our customers through unknown territory.

Jens Halsøe served as conceptual designer and later as project manager. He reflects on the project process and the initially non-existent requirements specification:

“There are many customers who struggle to define the task. They know they need help

because they lack the experience to set the right direction for their project.

For me, this project confirmed that at Kirkholm, our structured methodologies and experience

enable us to handle projects even when the requirements aren’t yet well defined.”

Opportunities for the future

The potential for future projects with FLSmidth has already been established as the case highlights both technical excellence and Kirkholm’s role as a strategic development partner, from concept to machine delivery. As recycling and sustainability grow in importance within the mining industry, the value of such solutions will increase.

With the second version of the machine in its early stages of development and a deeper understanding of the customers’ needs, Kirkholm is well-positioned to support similar projects.

Should we have a chat?

Do you have a similar project or a challenge where you need help with defining the solution? Do you have questions, does an introductory meeting sound interesting or would you like to know more about how Kirkholm works? Then we would be happy to offer a non-binding chat. Use the contact form or contact either our Sales Manager Nicolai or Area Sales Manager Henrik: