DANFOSS IXA

Danfoss IXA develops systems and sensors with a focus on energy optimization and measurement of exhaust gases for the maritime industry.

For several years Kirkholm has worked together with Danfoss IXA, where one of our common projects has concerned the the thermal environment of an emission sensor.

THERMAL CFD SIMULATION OF EMISSION SENSOR

Danfoss IXA has developed the emission sensor MES 1001, which makes it possible to measure the content of the harmful gases NOx, SO2 and NH3, which are emitted from the ships during operation, can be measured on the ships. In this way, it is always possible to make the necessary environmental documentation as well as monitor and optimize various processes on board.

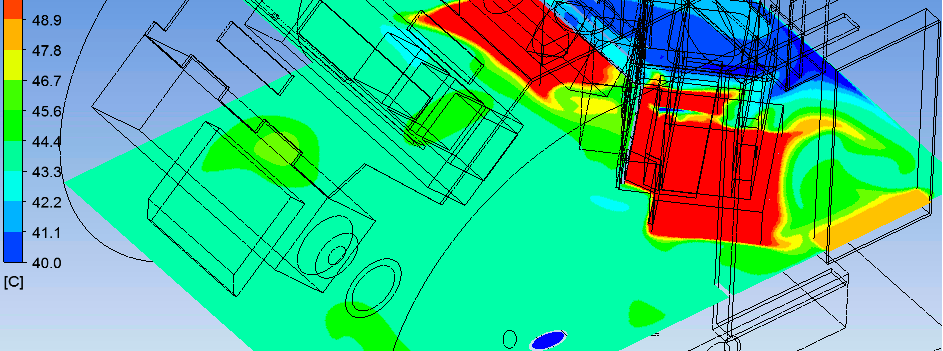

During the development of the emission sensor, Kirkholm has e.g. performed analyzes of the thermal conditions within the instrument, which is important as a sensitive detector is included in the design. The thermal conditions are especially critical, because the sensor is designed to make measurements on hot exhaust gases. This means that the instrument is exposed to external heat.

It is both costly and time-consuming to produce and test prototypes - especially when tests need to be done on a operating ship, and production of prototypes must be timed with sailing plans and actual installation on the ship. Therefore, Danfoss IXA also wanted to minimize the need for prototypes during the development process. Whilw using Computational Fluid Dynamics (CFD), Kirkholm was able to both identify the thermal conditions in the sensor and reduce the need for prototypes.

The accuracy of the simulations depends to a large extent on the setup of the boundary conditions so that they reflect the physical conditions correctly in the calculation model.

Therefore, the CFD collaboration with Danfoss IXA has been a 3-step process:

- Building the model

- Validating the model

- Final optimization process

CFD SIMULATIONS - OVERVIEW AND UNDERSTANDING

The fact that Kirkholm has been able to simulate different scenarios computationally has meant that the number of prototype iterations has been kept to a minimum. Likewise, it was overall possible to evaluate several solutions in the design process. The CFD simulations have helped to create an overview of the sensor's thermal design, while at the same time gaining a deeper understanding of critical parameters.

Kirkholm has contributed to increased knowledge about the product using CFD simulations, while Danfoss IXA has saved both development time and money. The use of CFD also made it possible to simulate operating conditions that are outside the sensor's specified range, and thus Danfoss IXA has been able to assess margins in the thermal design.

The CFD collaboration with Kirkholm has been absolutely necessary, says Allan Skouboe, Technical Director at Danfoss IXA:

"Thermal simulations are an absolute "must" when developing devices that must have a high reliability. High temperatures can reduce the life of your product dramatically, so it is therefore crucial that you focus on making a good thermal design, and here thermal simulations play an important role".